- Alignment Tester

- Brake Tester

- Jack Stands

- High Service Stands

- Service Jacks

- Trailers - Closed & Open

|

BBB Rating |

- Trailex

- Weaver Jack

- Weaver Safety Lanes

- Nationwide

- Direct Shipping

|

|

|

|

|

||

| 888-274-8490 |

|

![]()

![]()

Operation and Service

Manual for Weaver Jacks

![]()

|

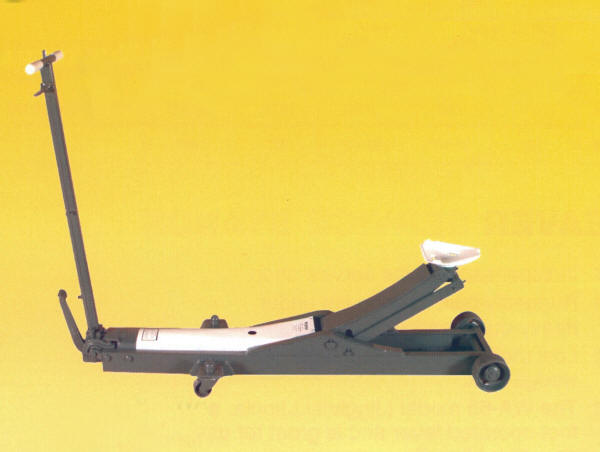

Weaver WA-73B Four (4) Ton Long Chassis

Hydraulic Service Jack

Weaver Jack Model Specifications

| MODEL |

CAP. (tons) |

FRONT WHEELS |

SADDLE STYLE AND SIZE |

FRAME LENGTH |

JACK WEIGHT |

| WA-72B | 2 | Two - 4" Diameter | Triangular or Round 5"' to 6" |

51" | 136 lbs |

| WA-73B | 4 | Two - 5" Diameter |

Triangular or Round 5" to 6" |

58" | 212 lbs |

| WA-75B | 10 | Two - 7" Diameter | Round 9" |

66" | 356 lbs |

| WA-85 | 20 | Three- 7" Diameter | Square 7" |

69" | 531 lbs |

If Your Jack Looks like a Weaver Jack, but it has a

different Manufacturers Label on it -

Some Manufacturers Private Label Weaver Jacks for sale under their Name -

|

Weaver Jack Operation For All Models Including:

To Assemble Your New Weaver Jack

1. Check the handle

set screw for tightness.

2. On the WA-85 20

Ton Jack only--Remove and discard the vent filler plug. This is very

important, as the vent hole must always be kept open so the Jack can

"breathe.”. The other models

have a breathable vent built into the cap.

3. Loosen the Piston

Ram and Pump Packing Nuts slightly.

They are tightened all the way down at the factory for shipment.

Tighten until no oil seeps out.

They only need to be moderately tight.

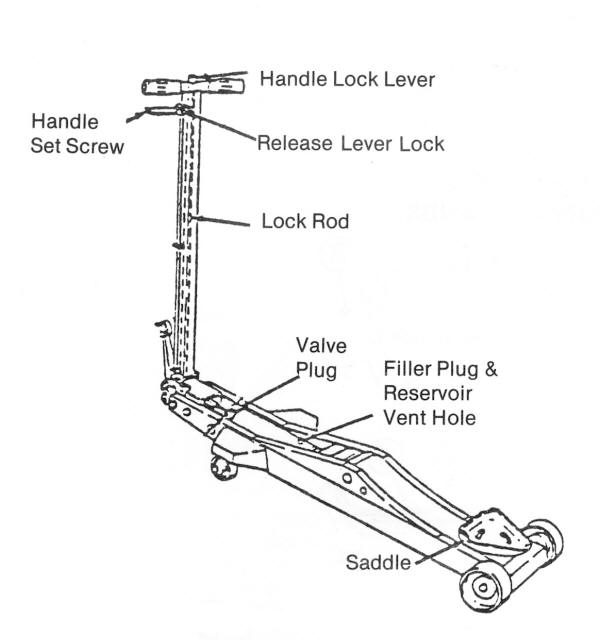

To Operate the Jack

WARNING:

Always use stands to support vehicle before attempting under vehicle

repairs or Inspections.

Always follow OSHA Workplace Safety standards.

1.

Use the Jack on a smooth, hard and level surface only.

Use the Jack only as a lifting device only.

2. Test the Jack by

using the foot pedal only to raise the saddle to full height without a

load. The pedal should

become very tight. If not,

check the oil level or see the troubleshooting section.

3. The Jack is easily

maneuvered by depressing the Handle Lock Lever until the lock rod

engages one of the two handle positions, and then pivoting the Jack on

Its rear casters.

4. Place the jack in

position so that the saddle will engage an approved lifting area of the

vehicle. The saddle is raised to the contact point by the foot pedal.

Lift the load using the long

handle – do not lift loads with the foot pedal alone.

On low clearance vehicles It Is

often advantageous to operate the foot pedal by hand while watches to

assure proper saddle contact. Surface on which Jack rests should be

fairly flat to prevent twisting of the frame. Load should be centered in

the saddle.

5. Pump with handle

for easy lifting. Do not attempt to raise the jack beyond It’s travel

stops.

6. To lower the load,

pull back gently on the release lever. Always

lower the load slowly.

7. Be certain that

area beneath vehicle is clear before lowering the vehicle. Always use

the release lever lock to prevent unintentional operation of the release

lever.

To Refill with Oil

Remove the filler

plug and with the saddle DOWN put InAW-32 Light Hydraulic Oil (or oil

that meets MIL•F•17111 011 specifications) until the level comes up to

within 1/4" to 3/8" below filler hole. Overfilling will cause oil to

spurt out the vent hole as the Jack Is lowered, or may' prevent jack

from lowering properly. Insufficient oil will cause the Jack to 11ft

only part way. Always be sure to put in oil only when the saddle is all

the way down. Be careful not to let any dirt get into the reservoir

while the Filler Plug Is out. Do

not use brake fluid, transmission fluid or any other fluids—doing so

could damage the seals and cause jack failure.

Overload Protection

The Lowering Valve

(Release Valve) is also designed to work as an overload protection

device. If you attempt to

raise a load that exceeds the jack’s rated capacity, this valve will

automatically release the cylinder pressure as an overload protection

safety feature.

Safety Precautions

Follow OSHA Standards

and ASME PALD Part 10 Instructions.

Never exceed the Jack’s rated load capacity.

Only lift vehicles at the recommended lift points found in the

vehicle’s service manual. Eye protection should be worn per OSHA

recommendations. Always use

the Jack on smooth, hard and level surfaces – while keeping the load

centered on the saddle.

Always check the Jack prior to each use – do not attempt to use the Jack

if any defect is observed.

Do not add accessories or modify the Jack in any way.

Always use Jack Stands under the vehicle and stay clear when

lifting or lowering the vehicle.

Preventive Maintenance

1. Inspect the jack

before each use. Take

corrective action before using the jack is a leak or defect is found.

2. Keep all working

parts thoroughly lubricated. Keep Jack clean.

Dirt is the major cause of Jack failure, and all openings should

be kept free of debris.

3. Packing nuts at

the piston and pump plunger should be kept moderately tight. These

Packings are NOT under high

pressure, and should only be tight enough to prevent leakage.

4. Keep oil filled to

within 1/4” to 3/8” of fill opening.

Replace oil at least once a year.

5. Ball Valve may be

removed for Inspection and cleaning by removing the Ball Chamber Plug

[V] and using a small magnet, remove the balls [X&Z] and the ball

weight[Y].

IMPORTANT:

Whenever it is necessary to loosen or remove the Ball Chamber Plug, the

Gasket [W] should be replaced with a new one. Oil leakage at this point

is usually caused by trying to reuse an old gasket over again.

To Relieve When Air-Bound

1.Should the oil

supply run too low, the Jack may become air-bound and work on only a

half stroke of the handle. Fill the jack with oil, and then raise the

saddle, and then using the Release Lever (lowering lever) lower the

saddle while holding the fool pedal depressed. This will flush out any

air in the system, and excess oil may then run out of the vent.

Repeat if necessary.

Be sure that the jack is properly filled with oil before putting

it back in service. Oil should cover the piston rod. If you cannot pump

the Jack Saddle to full height, raise the Saddle by hand and then

perform this operation

Ball Valve Test.

If the Jack will not

raise at all, then the Ball Valve may be obstructed by debris.

Open the Release Valve and keep it open.

Raise the Saddle lift arm manually to full height. Now lower the

Saddle by pushing it all the way down – this will flush out any debris

in the Ball Seats. Close the

release valve and try to pump up the Jack.

If it now will raise and hold, then the Ball Valve may need to be

serviced.

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Release Valve Group (upper ) - Pump Assembly (lower) | ||||||||||||||||||||||||

| Release Group - Needle Valve Adjustment | ||||||||||||||||||||||||

| CLICK HERE FOR ADJUSTMENT INSTRUCTION DETAILS | ||||||||||||||||||||||||

| Seal Kits for Weaver Jacks are available from Castle Equipment Company.. TIP – It is best to order the complete kit initially, rather than order individual parts, as it usually turns out that you will need multiple, if not all the parts in the Kit. You will end up saving money, as individual part prices will exceed the kit cost, not to mention that you would incur additional shipping costs. |

|

Print a Copy of This Operations & Service Manual CLICK HERE |

copyright 1997-2014

Castle Equipment Co.